FRP Grating

FRP Grating Specification

- Shape

- Rectangle

- Usage

- Commercial

- Material

- FRP

- Surface Treatment

- Plating

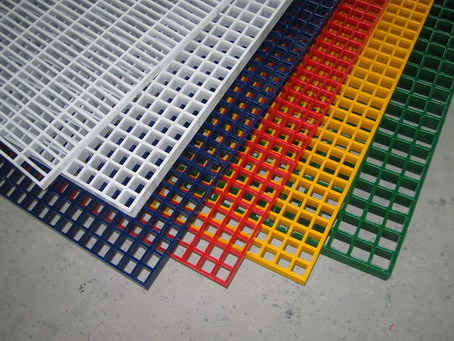

- Color

- Multicolor

FRP Grating Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 3-4 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Bubble Wrap

- Main Export Market(s)

- Middle East, Western Europe, South America, Central America, Eastern Europe, Asia, North America, Australia, Africa

- Main Domestic Market

- All India

About FRP Grating

| Recommendation of Correct Load application of grating | ||||||||||||||||||

| M.O.C of Grating : FRP | ||||||||||||||||||

| ||||||||||||||||||

| ||||||||||||||||||

| For any channel width above 450mm, our product recommendation for vehicular movement will be water gully covers | ||||||||||||||||||

| Angle Size for 30mm ht.grating : 35mm * 35mm * 5mm thk. | ||||||||||||||||||

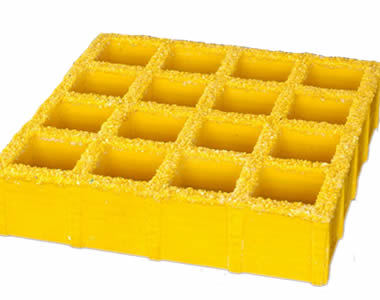

Optimal Surface Protection and Aesthetics

The plating surface treatment on our FRP gratings not only enhances visual appeal but also provides an additional layer of protection against wear, chemicals, and corrosion. Available in multicolor designs, these gratings seamlessly blend with different commercial environments, offering both style and functionality for flooring, walkways, and platforms.

Versatile Commercial Applications

Designed for commercial usage, our rectangular FRP gratings are perfect for multiple industrial sectors, including factories, warehouses, and public spaces. Their lightweight nature, resilience, and easy installation make them a preferred choice for professional applications requiring high load-bearing capacity and minimal maintenance.

FAQs of FRP Grating:

Q: How is the surface treatment applied to FRP gratings?

A: The surface treatment involves a specialized plating process that coats the FRP material, enhancing its resistance to corrosion, abrasion, and chemical exposure. This finish also contributes to the gratings multicolor appearance, making it suitable for visible or decorative commercial installations.Q: What types of commercial environments are ideal for using FRP gratings with plating?

A: These gratings are well-suited for a broad range of commercial settings, such as factories, processing facilities, public infrastructure, and service areas. Their durability and visual versatility allow them to accommodate high-traffic locations and demanding industrial conditions.Q: When should businesses consider installing FRP gratings over traditional materials?

A: Businesses should opt for FRP gratings when seeking materials that offer superior corrosion resistance, reduced weight, and lower maintenance compared to traditional steel or wood gratings. Whenever longevity and ease of handling are required, FRP gratings provide an effective solution.Q: Where are your FRP gratings manufactured and supplied from?

A: All gratings are manufactured and supplied from our facilities in India. As an exporter, importer, manufacturer, and supplier, we cater to both national and international commercial clients, ensuring reliable delivery and product quality.Q: What is the process for ordering FRP gratings for commercial projects?

A: Clients can initiate the order process by contacting our sales team with their specifications regarding size, color, and quantity. We guide buyers through material selection, customization options, and arrange prompt shipment and delivery to their location.Q: How are FRP gratings typically used in commercial settings?

A: FRP gratings are generally installed as floors, walkways, trench covers, or platforms within commercial facilities. Their robust design supports heavy loads while maintaining slip resistance and aesthetic value, which are essential for safety and productivity in professional environments.Q: What are the key benefits of choosing plated FRP gratings for commercial usage?

A: Plated FRP gratings offer enhanced protection from corrosion, easy maintenance, vibrant color options, and excellent mechanical strength. These advantages translate into reduced long-term costs and improved workplace safety, making them highly beneficial for commercial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FRP Gratings Category

Moulded Gratings

Minimum Order Quantity : 1 Piece

Shape : Square

Color : Red

Product Type : Moulded Gratings

Material : Other , FRP (Fiber Reinforced Plastic)

Surface Treatment : Other, AntiSlip Coated

FRP Anti Skid Grating

Minimum Order Quantity : 1 Piece

Shape : Square

Color : Yellow

Product Type : FRP Anti Skid Grating

Material : FRP

Surface Treatment : Plating

Mumbai, Maharashtra, India

|

FIBROCAST

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry